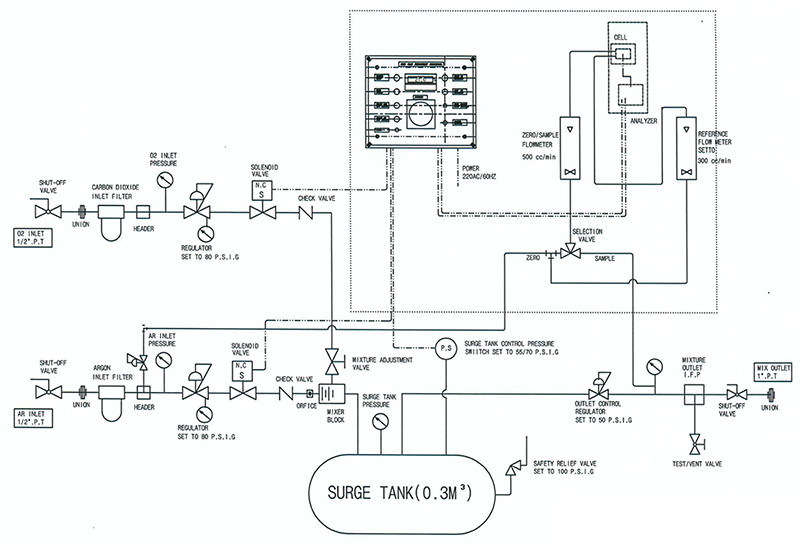

Gas Mixer print DIAGRAM print

Gas Mixer

BUIK GAS MIXING MACHINE FOR WELDING SHIELD. FURNACE ATOMOSPHERE, FOOD PAKAGEING AND LEAK DETECTION.

Two types of gas are to be mixed is supplied to the mixer from a

storage tank BUIK.

Usually the pressure of these gases is supplied to keep the

7㎏/㎠ ~ 9㎏/㎠ enters the so 0 ~ 4㎏/㎠.

The two types of GAS in MIXER are automatically adjusted to the

same internal pressure. MAJOR GAS adjusted by the regulator

to flow through a fixed ORIFICE. MINOR GAS flows through the

METERING VALVE is actuated by the adjustable orifice two gases

are mixed and injected into the SURGE TANK.

If the pressure drops below the pressure required in the surge

tank As repeated by opening of the solenoid valve by the pressure

switch is working mixture gas is supplied to the PROCESS.

GAS analyzer continuously analyze the ratio of the gas and this

time may be mixed in a certain ratio to adjust the GAS METERING

VALVE according to gas ratio, and can be a continuous supply.

Appropriate ratio of the gas is held constant, while opening the closed valve in flow direction of the flow.

Typically, the gas to be mixed in a mass storage tank is fed so that the gas mixture produced in the mixer is supplied to the production Process through the pipeline. Also it has been designed to be suitable for a number of diferent manufacturing processes that various typical applications are shown in the left.

Operator is operating the metering valve of the gas flow while the major and minor gas can be adjusted to an appropriate ratio of mixed gas to be used while simply the value of the analyzer.

Gas mixer is 60NM3 / Hr, 100NM3 / Hr, 150NM3 / Hr, and may be fabricated of a different capacity, each of these models are made of a weather-proof type that is not limited to the use location and weather.

EXAMPLE

| CO₂/ Ar | WELDING SHIELD GAS |

| O₂/ Ar | |

| He / Ar | |

| H₂/ Ar | |

| H₂/ N₂ | FURNANCE ATMOSPHERE |

| CO₂/ N₂ | FOOD PACKAGING |

| O₂/ CO₂ | |

| He / N₂ | LEAK DETECTION |

| He / Air | |

| N₂/ Ar | LAMP FILLING |

| He / Ar |

ACCURACY

| ±2% OF FULL SCALE OVER 15 T O 30℃ TEMPERATURE RANCE |

| (STATED ACCURACY ASSUMES THAT THE IMPUT TEMPERATURE OF GASES ARE EQUAL) |

FLOW - DIAGRAM

SPECIFICATION DIMENSIONS AND GAS CONNECTIONS

| Model No. | CAPACITY | RANGES(OTHER RANGES)AVAIABLE | HEIGHT | WIDTH | DEPTH | CONNECTIONS |

|---|---|---|---|---|---|---|

| UNS-9000A-1 | 0~60N㎥/Hr | 0~50% CO₂ IN ARGON | 1200 | 1200 | 700 | 1/2″PT, 3/4’PT |

| 0~10% OXYGEN IN ARGON | ||||||

| 0~50% HELIUM IN ARGON | ||||||

| 0~50% CO₂ IN NITROGEN | ||||||

| 0~50% H₂ IN NITROGEN | ||||||

| UNS-9000A-2 | 0~100N㎥/Hr | SAME AS ABOVE | 1300 | 1400 | 800 | 1/2″PT, 3/4’PT |

| UNS-9000A-3 | 0~150N㎥/Hr | SAME AS ABOVE | 1600 | 1540 | 800 | 3/4″PT, 1’PT |

| *capacity other than the standard capacity is available to order | ||||||

GAS ANALYZER

| TCD TYPE(THERANAL CONDUCTIVITY DETECTOR)ALL MODEL DIGITAL TYPE ADOPTED | |

| NOMAL SUPPLY GAS INLET PRESSURE | 7~9㎏/㎠ |

| NOMAL MIXED GAS OUTPUT PRESSURE | 0~4㎏/㎠ |

| SURGE TANK | 150L~200L(WATER CAPACITY) |